Resuming Program or Jump to Line

When machining complex jobs such as die molds or complex engraving jobs which can take a long time to machine, power failure or broken tool means that you need to start the entire Gcode file from start.

Restarting the Gcode file from start is very time and resource consuming.

To be able to effectively restart your machining process from where you left, MASSO has a Resuming Program or Jump to Line feature.

- Please note that Jump to line is not currently available for Lathe.

- With this feature the current Gcode line number is saved into a high speed internal memory and even if the machine is powered off while machining,

- MASSO will automatically store that last line number in memory as it machines.

- The line number used in Jump to Line is the first line of Gcode that will be executed when MASSO resumes machining. In calculating the starting position MASSO moves to the position immediately before the selected line so that it can machine the selected line of Gcode when it resumes.

- If you select a line of Gcode with a tool change as the starting point, because MASSO starts one line of Gcode previous so that it can perform the requested line of Gcode it will change to the previous tool in preparation and then executed the requested line and change the tool change.

- Jump to Line can be called from within the Gcode Editing page using the Resume Machining from Line button.

Resuming a cut

- Power on your machine if the machine is off

- Home the Machine if the machine was powered off, the E-Stop was used or you have lost position.

- Go to the F6-Load File screen and load your Gcode file if it is not already loaded it by pressing the F6 key on your external keyboard or the F6-Load File button on screen

- Go to F2-Program & MDI screen by pressing the F2 key on your external keyboard or the F2-Program & MD button on screen

- Press the Jump to line button

or use CTRL+J from an external keyboard to open the Resuming Program window.

or use CTRL+J from an external keyboard to open the Resuming Program window.

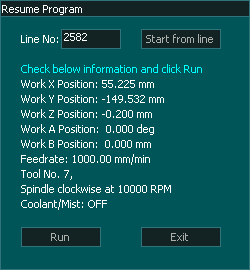

- The last line number machined will automatically be filled and depending on your program, please go back a few lines from the last running line so that the machining is resumed a few lines before it stopped.

- Select Start from line button

and MASSO will process the Gcode file up to the line number entered by you.

and MASSO will process the Gcode file up to the line number entered by you. - When done MASSO will calculate all the machining parameters from the Gcode file and display them on screen

- Carefully check the information and click the Run button.

- The Z axis will move to the Home position and the X axis will move to its starting position

- Press the Cycle start button

after each axis move after confirming that axis has moved to its correct starting position

after each axis move after confirming that axis has moved to its correct starting position - The last axis to move into position will be the Z axis.

Resuming from the Edit screen

From MASSO G3 or MASSO Touch Gcode edit screen you can select the line of Gcode that you wish to start from.

- Click on Edit button

in the F6-Load_File page to open the Gcode program

in the F6-Load_File page to open the Gcode program - Page down and select the line of Gcode you wish to start from by putting the cursor on the line.

- Press the Resume Machining from Line Button

on screen.

on screen. - MASSO will close the editor and enter the Jump to line page with the line number already filled in for you.

- Select Start from line button

and MASSO will process the Gcode file up to the line number entered by you.

and MASSO will process the Gcode file up to the line number entered by you. - When done MASSO will calculate all the machining parameters from the Gcode file and display them on screen

- Carefully check the information and click the Run button.

- The Z axis will move to the Home position and he X axis will move to its starting position

- Press the Cycle start button

after each axis move after confirming that axis has moved to its correct starting position

after each axis move after confirming that axis has moved to its correct starting position - The last axis to move into position will be the Z axis.

INFORMATION: If you select a line of Gcode with a tool change as the starting point, because MASSO starts one line of Gcode previous so that it can perform the requested line of Gcode it will change to the previous tool in preparation and then executed the requested line and change the tool change.

Jump to Line in Plasma software

When using the Jump to line in Plasma software MASSO will search backward in the Gcode file to locate the last M5 or M3 command depending on the software version being used and will be the starting line.

If the line you have selected is an M5 command it will use that line.

If there is no previous M5 or M3 command it will return to the start of the Gcode file.

The use of Plasma Jump to line works the same as Mill software in its operation.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese