Plasma Torch and MASSO DTHC

Plasma Torch can be used with and without the MASSO DTHC.

- Tool 112

- To change Plasma issue a T112 M06 command in MDI and include this in your Gcode file to ensure that it changes to the correct screen when you run your Gcode file

- This integrates Plasma and Mill into the same software so that a user with a dual machine does not need to switch between software to use one or the other.

- The X, Y & Z offset relative to the main spindle can be entered in the Multi-Head Setting page

- A Torch Touch offset is provided to account for the activation distance required to trigger a touch switch.

- Ohmic and touch switch can be used for setting the Plasma torch height.

- Plasma Up/Down is provided to move the Plasma torch into position if this is a multi head machine. eg Plasma and spindle.

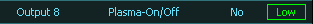

- A Plasma On/Off is provided to turn the Plasma Arc on and Off.

- A piercing count is recorded on the F2 screen to allow the user to keep track of wear on consumables. This value is retained in memory when power is turned off.

- The Plasma Torch can be used without a THC if it is not required.

- THC support will be provided via the MASSO DTHC module and older Up / Down THC units.

- The MASSO DTHC module has been developed to work exclusively with and integrate into the Plasma Torch Multi-Head software.

- For more information on the DTHC please see MASSO_DTHC

- For more information on setting up legacy THC's please Click Here

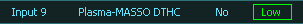

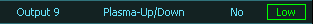

- A dedicated input is provided on MASSO input 9 for the MASSO DTHC Input. No other input can be used for the MASSO DTHC input.

- A new Gcode G200 has been introduced to work with Plasma and is an integral part of the MASSO DTHC Module but will also be used with legacy THC's as well.

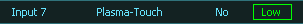

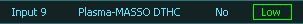

Assigning MASSO DTHC Input

INFORMATION: The normal state of the Plasma-MASSO DTHC input when working and idle is constant change between High and Low. If the input shows a constant Low state please check your connection.

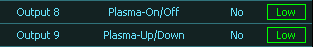

Assigning Plasma Inputs

Assigning Plasma Outputs

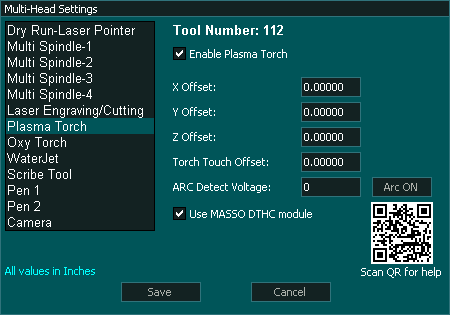

Multi-Head Setting

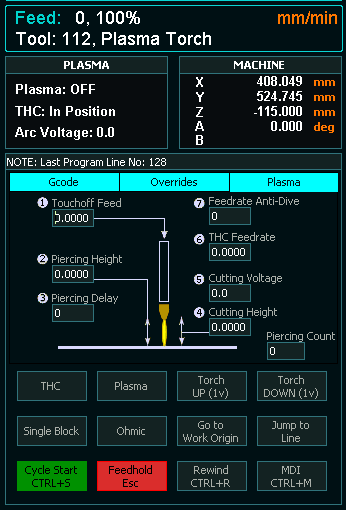

F2 Screen

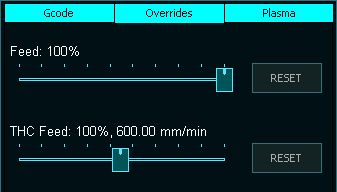

- 7 Parameters are provided on the F2 Plasma tab to allow easy adjustment of the Plasma torch while it is cutting.

- Each parameter box can be clicked on and a new value entered into the box.

- Touch off and Piercing is automated in MASSO Plasma and will occur on each M3 command before moving to the cutting height and these are controlled by parameters 1 to 4

- The THC voltage can be set directly on MASSO and changed either by entering a new value or using the Torch Up / Down buttons on screen which will change the voltage by 1 volt.

- The THC feed rate can be adjusted as needed and this adjusts the speed of the Z axis when under THC control.

- Feed rate Anti dive is a percentage of the X Y axis feed rate and should it fall below this value the Z axis will lock when under THC control to prevent the torch falling and touching the material.

- Parameters 1,2,3,4,5 & 7 can be set as part of the Gcode file. Gcode command G200

- Parameter 6 is set using Gcode command M667

- Touch off Feedrate

- Piercing Height

- Piercing Delay

- Cutting Height

- Cutting Voltage

- THC Feedrate

- Feedrate Antidive

Configuration

- Enable Plasma Torch in the Multi-head screen.

- Assign an input for Plasma-Ohmic id using Ohmic touch.

- Assign an input for Plasma Touch is using a touch switch.

- Assign an input for Plasma-Torch Breakaway.

- Assign an input for Plasma-MASSO THC is using a THC.

- Enter the X, Y and Z axis offset from the reference tool into the Plasma Torch Multi-Head setting screen. This could be the offset from the Main spindle if using one but if this is a stand alone Plasma machine them leave these values at 0

- Enter the Torch Touch Offset value if using a Plasma touch with a built in switch.

- Assign a Plasma output for Plasma-Torch On/Off.

- Assign a Plasma-UP/Down if your Torch needs to be moved into position.

Plasma Logic

- The Plasma-Up/Down output goes Low to move the Torch in to the up position.

- A THC feed rate Override is provided under the Override tab and can be adjust the THC feedrate in real time

THC feed rate override

Installing and setting up MASSO DTHC

Information on installing and setting up the MASSO DTHC can be found here

Information: Older up/ down THC units can be used with the new Multihead software. Arc OK, THC Up and THC Down can be assigned as shown in the Proma THC 150 section of the documentation.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese