G200 - Plasma Parameters

This command defines the parameters for Plasma.

It can be placed at the start of the Gcode file and will populate the Plasma parameters shown on the Plasma Tab in the F2 screen

To access the Plasma screen you must select Tool 112. In MDI enter T112 M6 to change to the Plasma screen.

It is good practice to add T112 M6 to your Gcode files.

INFORMATION: This Gcode is not available for MASSO G2

Syntax & Parameters

- G200 uses the values to populate the Plasma parameters tab

- F Value – Touch off feed rate

- P Value – Piercing Height

- D Value – Piercing delay This value is defined in Milliseconds

- C Value –Cutting height

- V Value - Cutting voltage

, if set to “0” then the system goes into the “Auto Voltage” option where the system samples the voltage at cutting height and then maintains this voltage for the rest of that cut. To make use of this parameter the MASSO DTHC module is required.

, if set to “0” then the system goes into the “Auto Voltage” option where the system samples the voltage at cutting height and then maintains this voltage for the rest of that cut. To make use of this parameter the MASSO DTHC module is required. - A Value - Feed rate Anti Dive

, (Please note that this parameter has not yet been implemented) This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value.

, (Please note that this parameter has not yet been implemented) This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value. - O Value - Ohmic ON/OFF. 0 is Ohmic OFF, 1 is Ohmic ON.

- S Value - Stop after piercing and wait for Cycle start. 0 is do not stop, 1 is Stop and wait for Cycle Start.

INFORMATION: If the Cutting voltage  is set to 0 in G200 MASSO will use “Auto Voltage” option where the system samples the voltage at cutting height

is set to 0 in G200 MASSO will use “Auto Voltage” option where the system samples the voltage at cutting height  and then maintains this voltage for the entire cut. Should you find that the torch height is too high or too low you can type in a new value in the on screen cutting voltage box

and then maintains this voltage for the entire cut. Should you find that the torch height is too high or too low you can type in a new value in the on screen cutting voltage box  or use the on screen Torch up or Torch Down button to adjust the torch height in real time.

or use the on screen Torch up or Torch Down button to adjust the torch height in real time.

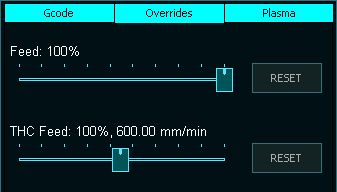

INFORMATION: The THC Feed rate parameter  is specified using the M667 F Gcode. If you find that the THC feed rate is too fast or too slow you can manually adjust the feedrate on the Override page using the THC Feed: slider.

is specified using the M667 F Gcode. If you find that the THC feed rate is too fast or too slow you can manually adjust the feedrate on the Override page using the THC Feed: slider.

Caution: The A Value - Feed rate Anti Dive  has not been implemented at this time but will be added in the future and this documentation updated.

has not been implemented at this time but will be added in the future and this documentation updated.

Example program

N10 G200 F150 P5.5 D500 C3.1 V116 A50 O1 S0

G200

A G200 with no parameters after it will turn off the G200 operation and the plasma will work in a legacy mode where all operations need to be done manually using Gcode.

The default setting for G200 when MASSO is powered on is G200 is turned on so if running old files a G200 command should be added to the start of the file to switch MASSO to legacy mode.

This can also be done by issuing a G200 in MDI but adding it to the file better.

Once G200 is turned off it will remain off until turned on again or MASSO is repowered.

G200 can be used with an external THC unit such as a Proma 150 and is mandatory when using the MASSO DTHC unit.

When G200 is active many of the standard plasma operations are automated which greatly simplifies the Gcode required.

When an M3 is issued the following start sequence will happen automatically.

- Probing will start automatically using the F parameter as the probing feed rate. once the touch off been triggered the torch height will be set.

- The torch will automatically move to piercing height defined in parameter P

- The torch will start the arc

- On receipt of the Arc ok signal the piercing Delay timer defined in parameter D will start.

- At the end of the delay time the Torch will automatically move to the cutting height defined in parameter C

INFORMATION: It is recommended that GCode use the G200 features whether you are using a DTHC or an older Legacy THC unit.

F - Touch off feed

This is the Touch off feed rate used in the automatic probing as part of G200 when it is active

P - Piercing height

This defines the Piercing Height used as part of G200 when it is active.

It is the height the torch will move to perform the piercing.

D - Piercing delay

This is the piercing delay used as part of G200 when it is active.

This is the time the torch will wait for the material to be pierced before continuing to cutting height.

This value is defined in mS eg a value of 2000 is 2 Seconds

C - Cutting height

This is the cutting height used as part of G200 when it is active.

This is the height the torch will automatically move after the piercing is complete.

V - Cutting voltage

This defines the cutting voltage that the MASSO DTHC uses to set the torch height when cutting.

If a voltage is defined it will maintain this voltage while cutting.

The voltage can be altered in real-time by using the Torch UP and Torch Down buttons on the F2 screen

Each press will change the voltage by 1 volt.

A new value can be typed into the cutting Voltage box on the Plasma tab on the F2 screen

If the V Value is set to 0 in G200 MASSO will use the “Auto Voltage” option where the system samples the voltage at cutting height each time the plasma starts and then maintains this voltage for the rest of that cut.

A - Anti-dive

Please note that this parameter has not yet been implemented but will be added at a future date)

This defines the feed rate anti-dive percentage value. It is used to lock the Z-axis when the axis slows down to prevent the torch from dropping into the material. This normally occurs when cutting arcs.

This value is a percentage of the X & Y axis feed rate below which the Z-axis will lock when under THC control to prevent the torch from moving into the material. The axis will unlock and the THC resume operation once the feed rate increases above this value.

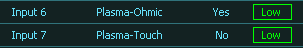

O - Ohmic

This is the Ohmic touch off parameter.

MASSO has 2 touch off inputs that can be used for Plasma touch off. Plasma Touch and Plasma Ohmic

When O0 is set the Plasma-Touch is used. This is usually a switch built into the torch that activates then the torch is pressed into the material surface.

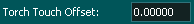

Then this input is used the Torch Touch Offset is used to calculate the torch height.

When O1 is set the Plasma-Ohmic is used. This type of touch off uses the electrical connection between the torch tip and the material itself to detect the torch height.

The Ohmic touch does not use an offset value.

You can configure both touch types on your machine and select the one best suited at the time.

Only one can be active at a time.

You can manually switch between them by using the Ohmic Button

Ohmic is active when it is Yellow

S - Stop

When piercing thicker material the molten metal is moved to the surface of the material until such time as the material is pieced.

This can cause a build up on the surface of the material that the torch can run into.

Use of the S parameter in the G200 can be used when cutting material that presents this problem.

When S1 is set, and an M3 command is issued the torch will touch off the material, move to the piercing height and after the piercing delay has finished the Plasma will turn off and the torch ascend to the Z home position.

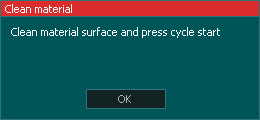

This message is displayed on screen

The material surface can now be cleaned and when ready the Cycle Start button is pressed.

The torch will now rapid down to the cutting height, the Plasma will start and the cut will commence.

This sequence will occur on each M3 command.

If S0 is set there will be no stop between piercing and moving to cutting height.

Default is S0 when MASSO is powered on

The last S value will be remembered until it is changed or MASSO is repowered.

Build up left after piercing thick material

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese