Checking Optocouplers

If any of the optically isolated inputs on the controller do not work then the below steps can be done to find the cause of the problem.

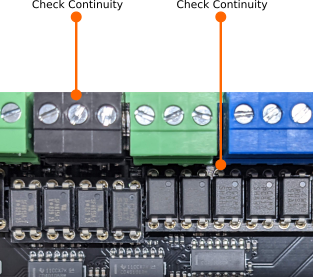

Step 1: Checking ground side continuity

With a multimeter check, the continuity between the black connector and the below-marked pin of the optocoupler input that's not working.

If there is no continuity then it can be caused because of the below reasons:

- The optocoupler is not plugged in properly.

- The track on the circuit board has been damaged.

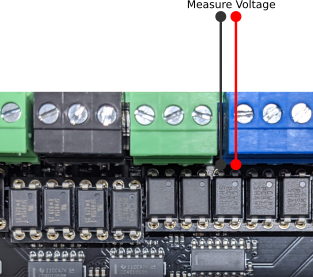

Step 2: Measuring input signal voltage

Connect a 5v to 24v signal to the input that is being tested and measure the voltage on the below-marked points.

This voltage should be around 1.1v. If this voltage is not received then it can be caused because of the below reasons:

- The optocoupler is not plugged in properly.

- The track on the circuit board has been damaged.

- The resistor for this optocoupler is damaged.

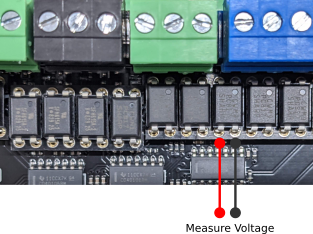

Step 3: Measuring output signal voltage

Ensure that no signal is connected to the input and measure the voltage on the below-marked points.

This voltage should be around 3.1v.

Connect a 5v to 24v signal to the input and measure the voltage on the below-marked points.

This voltage should drop to around 0.14v. If this voltage is not received then it can be caused because of the below reasons:

- The optocoupler is not plugged in properly.

- The optocoupler is damaged.

- The track on the circuit board has been damaged.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese