This documents how MASSO G3 & MASSO Touch works in conjunction with the G200 Gcode command in Version 5.0 software and above.

Please ensure that you read and understand this relationship.

INFORMATION: For detailed setup information of Plasma on a MASSO G3 please follow see >>HERE<<

To use Plasma you must select Tool 112.

You can do this in Gcode with the command T112 M6 or by typing it into MDI

MASSO will remain in this tool until it is changed to another.

MASSO remembers which tool was in use when it is powered off and will boot up on the same tool when powered on.

Gcode

The G200 Gcode command in Version 5.0 software and above.

This Gcode is used to address parameters on the DTHC module as well as automate some of the plasma processes such as Probing, Piercing and setting cutting height.

Use of G200 is required for DTHC use.

Please ensure that you read and understand this relationship.

For more information on G200 please click >>Here<<

How Plasma works

- Gcode command issued eg. T112 M6. (This set MASSO to the Plasma tool.)

- The Plasma-Up/Down output goes high to move the Torch in to position. This is usually done on a multi-head machine with pneumatic cylinder and not needed is the Plasma torch is the primary head or does not need to move into position.

- When the Gcode file is loaded and run it will populate the cutting parameters into the Plasma tab using the information in the G200 Command.

- The M3 command will start the Plasma torch will automatically touch off on the material

- It will then move to the piercing height

- Start the Arc and wait for an Arc Ok

- On the receipt of an Arc ok it will wait the time specified in the Piercing Delay

- At the end of the delay it will move to the specified cutting height.

- Piercing count is incremented to allow the user to track the wear on the consumable.

- MASSO will then proceed with the Gcode file.

- If there is a MASSO DTHC installed, when the THC is turned on using M667 F??? the DTHC will assume control of the Z axis height and it will use the Cutting Voltage specified to keep a constant height above the material.

- If the X,Y Feed rate falls below the amount specified in the Anti-Dive value the Z axis will lock to prevent the Z axis crashing into the material and will resume once the feed rate returns to a valid speed. (under development)

- M666 will turn off the THC

- Parameters 1-7 can be adjusted in the Plasma Tab by selecting the box and typing in a new value. This can be done while machining is in progress to fine tune the cutting.

- Torch up and down buttons are provided on the F2 screen to allow fine tuning to the torch height. This will adjust the cutting voltage by + or - 1 volt.

- M5 will turn off the Plasma Arc.

- Changing to a different tool will cancel Plasma mode.

- The Plasma-Up/Down output goes Low to move the Torch in to the up position when a different tool is selected.

- The manner of Plasma operation is the same for a machine using a legacy THC unit with the exception that the voltage setting is done manually on the THC unit and the V parameter is ignored.

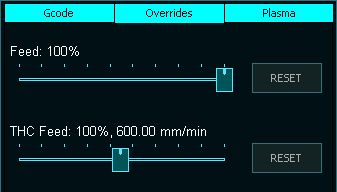

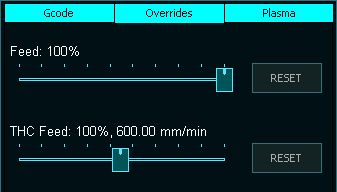

Overrides Tab

For easy adjustment while cutting is in progress the overrides tab has two sliders that the user can use to adjust machining speed in real time.

The Feed slider will adjust the X & Y axis feed rate speed from 10 to 100%

The THC Feed slide allows you to adjust the Z axis feed rate between 20 & 200% in real time to allow you to fine tune the Z axis movement when the THC is runing

If you find that your Z axis is hunting up and down uncontrollably seeking the correct z height under DTHC control this will allow you to slow it down until it becomes stable and follows the material correctly. Take a note of the feed rate on screen and you can use it in future Gcode files.

Overrides Tab

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese