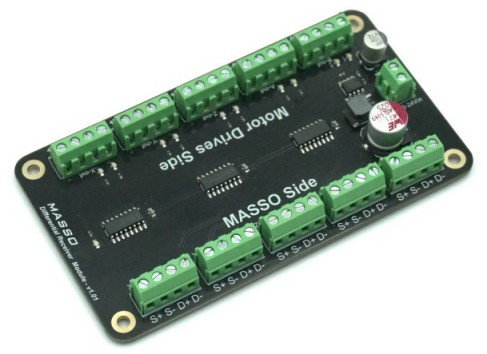

When to use the MASSO Differential Receiver Module

- The MASSO Differential Receiver Module is designed to provide support for Stepper or Servo motor drives that do not support advanced differential signals.

- Differential signals provide great immunity to electromagnetic noise that can interfere with motor control signals and cause issues with motor positioning or might cause unexpected motion on the machine axis.

- VFD drives for spindle motors and plasma cutting sources generate high electromagnetic noise and can interfere with motor position signals.

- With differential signals, long cables with STEP and DIRECTION signals from the MASSO controller can be run to the motor drives.

- Do not mount the Differential receiver next to the controller. Mount it next to the drives.

- Up to 50m between MASSO and the MASSO differential receiver module can be achieved when using a high quality twisted pair cable with uniform impedance and low attenuation.

- The distance between the MASSO differential receiver and your Drive should be kept as shot as possible.

INFORMATION: The MASSO Differential Receiver Module can be used to control up to 5 axis motor drives and can also provide 5 volts so that no external 5 volt power supply is required.

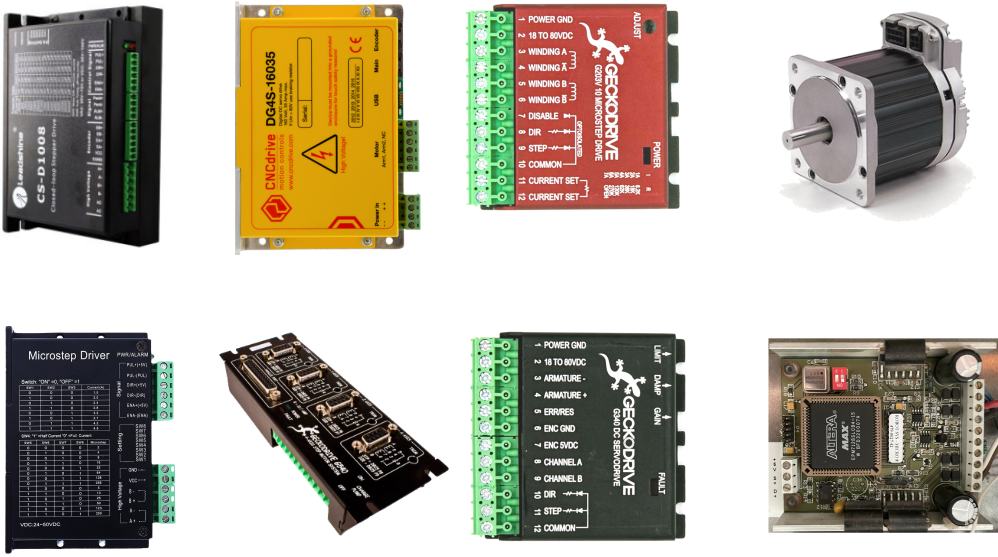

Some of the example drives that do not support differential signals

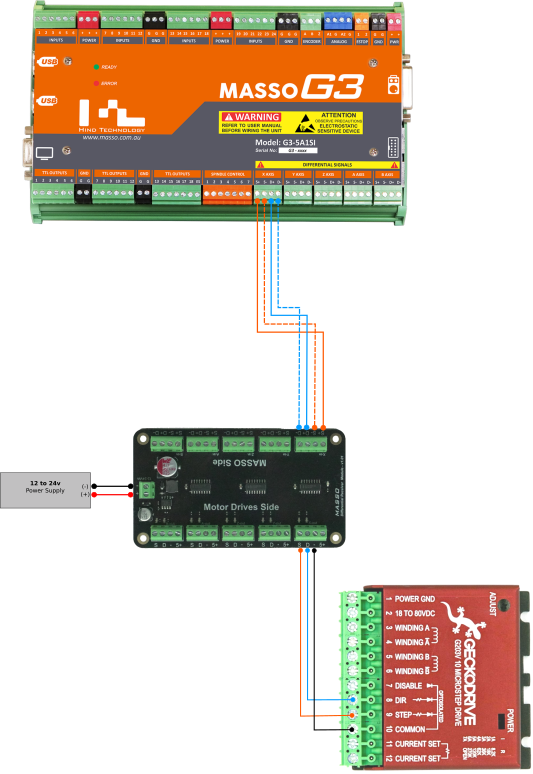

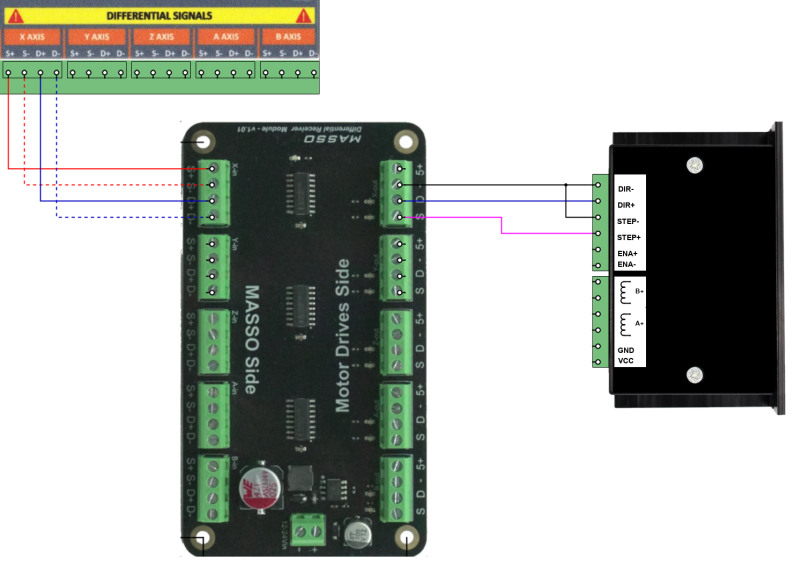

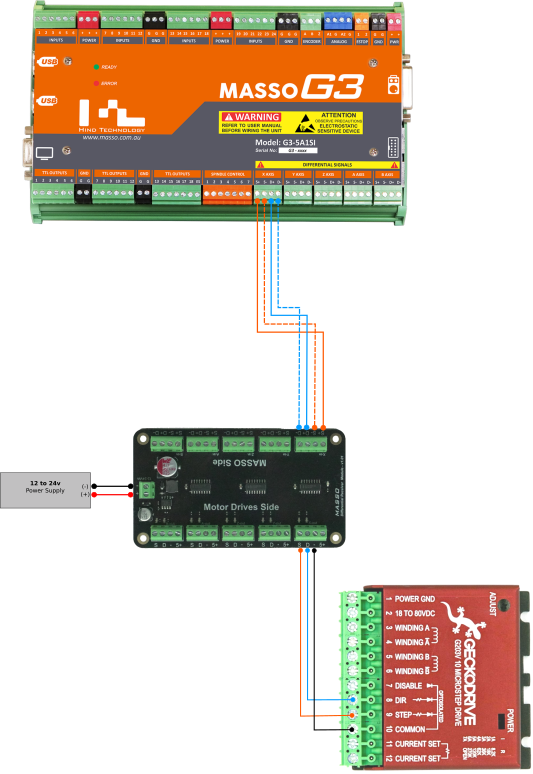

Wiring example with a common negative signal

The below diagram shows a GECKO G203V drive that takes TTL signals with a common negative.

Mount the Differential receiver close to the drives.

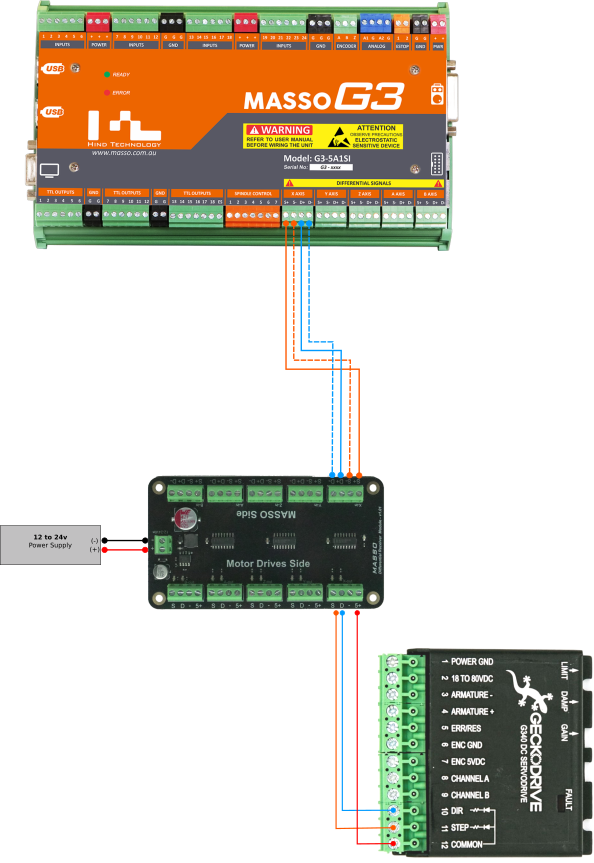

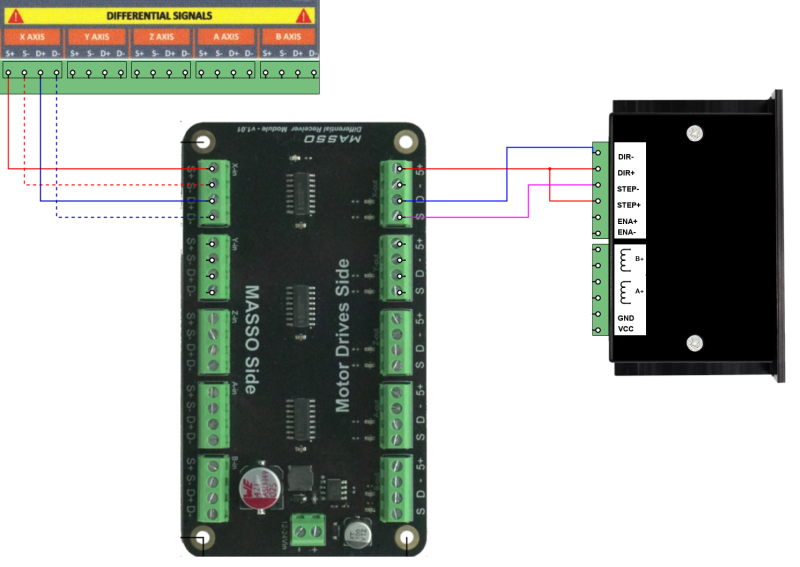

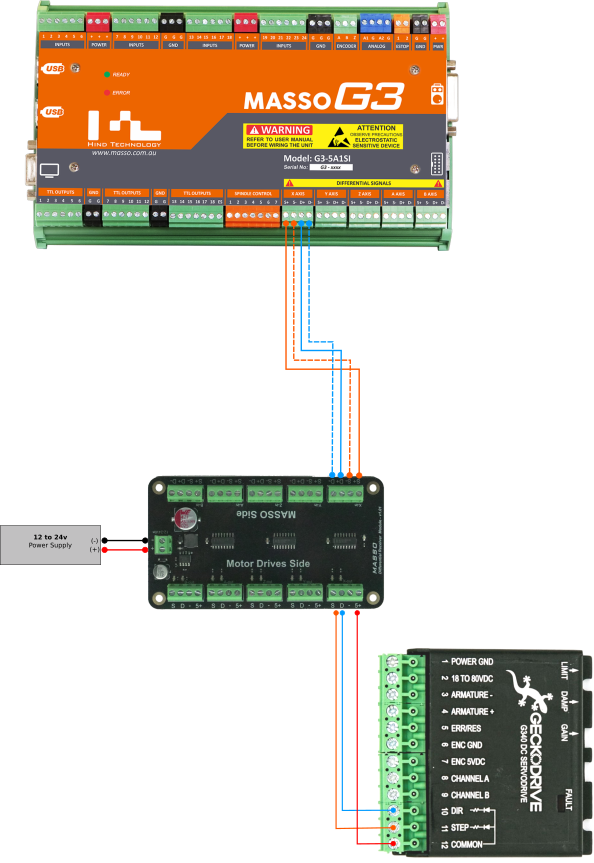

Wiring example with a common positive signal

The below diagram shows a GECKO G340 drive that takes TTL signals with a common positive. The MASSO Differential Receiver Module provides 5 volts and no external 5 volt power supply is required.

Mount the Differential receiver close to the drives.

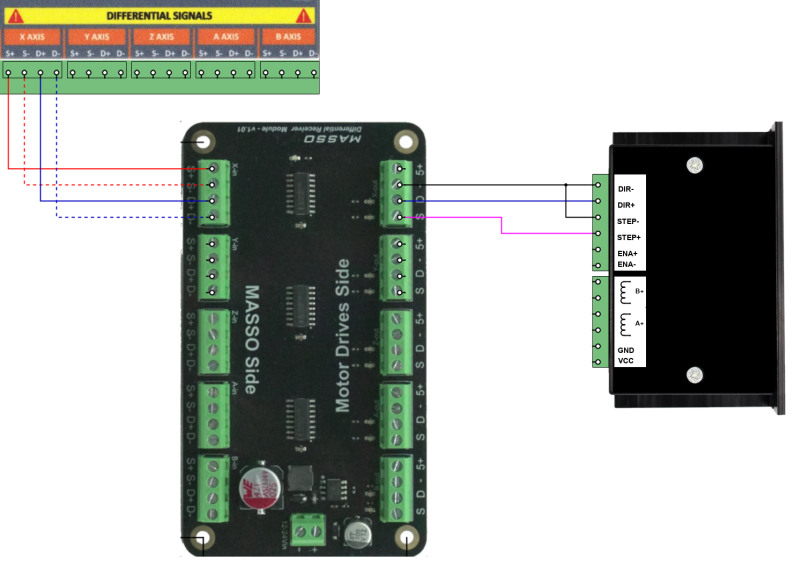

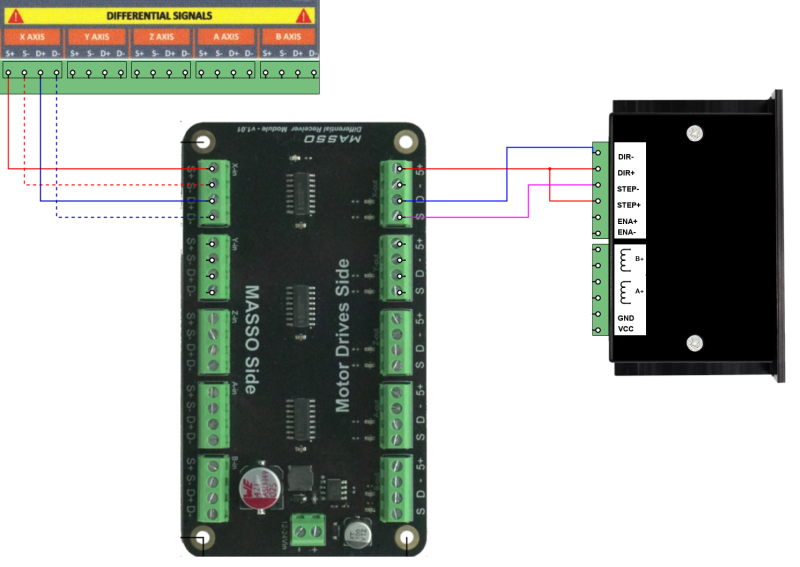

Wiring example of a 4 wire optically isolated drive

MASSO differential drive wired in current Sourcing configuration

MASSO differential drive wired in current Sink configuration

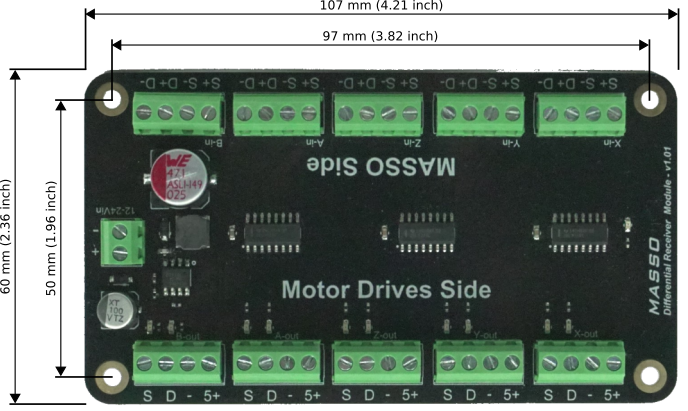

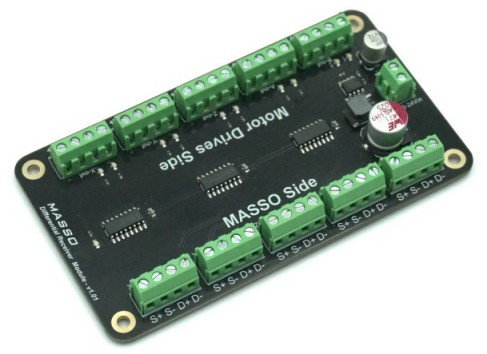

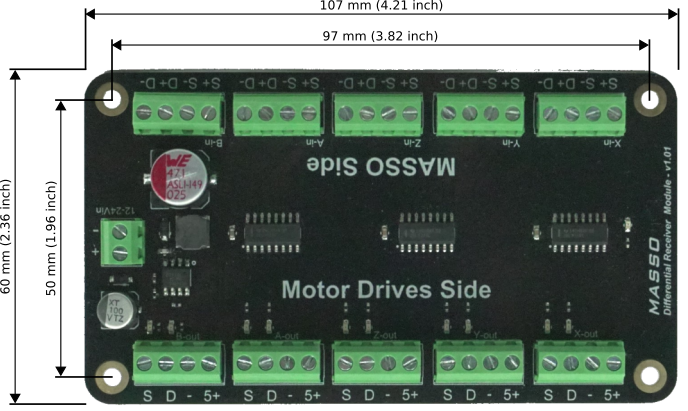

Mounting and Mechanical Data

5+

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese