MASSO Optical Encoder

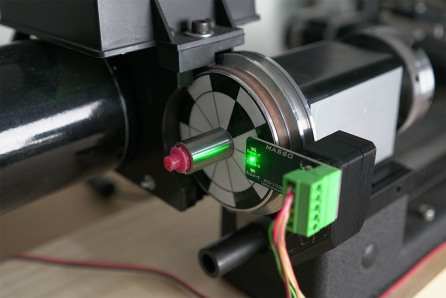

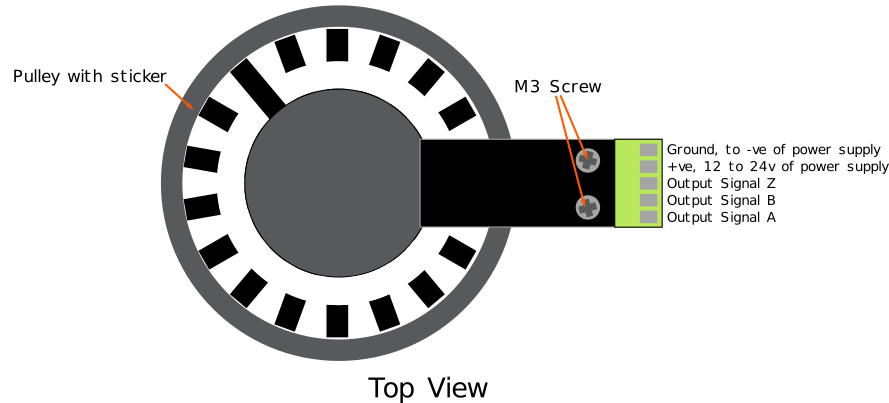

MASSO contactless optical quadrature encoders are based on a non-mechanical design. By not having any moving parts, the sensors have very high accuracy and very low failure rate. The encoders can be easily mounted in front of your Lathe’s spindle pulley to provide full quadrature encoder signals for multi pass threading.

- High accuracy with no moving parts.

- Easy to mount with no pulley or timing belts required.

- Wide working voltage range 12 to 24VDC.

- Easy mounting using M3 screws.

CAUTION: Output signals are 0v for LOW signal and 10v for HIGH signal.

INFORMATION: The maximum pulse frequency on encoder inputs for MASSO G3 controllers is 60kHz.

INFORMATION: The maximum pulse frequency on encoder inputs for MASSO G2 controllers is 8Khz. The MASSO G2 can be upgraded to 20Khz by replacing the Encoder Optocouples. For more information on this please see: Upgrading the spindle encoder G2

Generate Encoder Disk Label

Simply click the below "Generate Encoder Disk" link to quickly generate the encoder disk label by entering the pulley Outer Diameter (OD) and Inner Diameter (ID).

Generate Encoder Disk

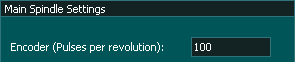

When using the encoder label generated using the link above, count the number of Black segments on the outside ring and enter this into the PPR box in the Spindle settings.

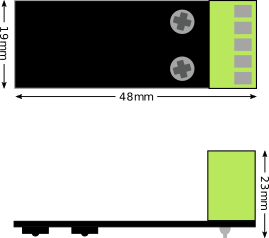

Mechanical Dimensions

Installing and Wiring

CAUTION: Connecting the power polarity in reverse will damage the sensor.

MASSO Spindle Encoder

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese