Tool Setter

A tool setter or a simple touch plate can be wired to MASSO to be used with interactive part probing or with G38.2 probing cycle gcode command.

INFORMATION: For information about interactive part probing CLICK HERE

INFORMATION: For information about using G38.2 probing cycle CLICK HERE

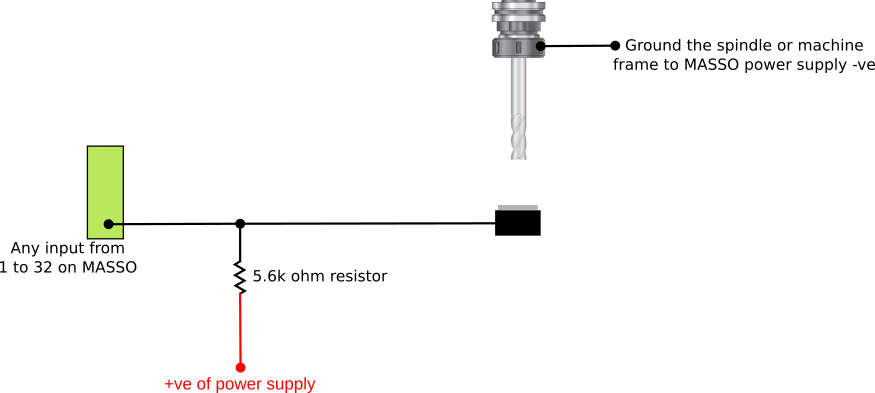

Wiring example of a simple touch plate

This circuit is of a simple touch plate where the plate and the cutter complete the circuit when they touch.

The pullup resistor used in this circuit pulls the input high and the input logic must be inverted to show low when the tool setter is not triggered.

The pullup resistor should be a minimum of 1/8 watt.

This is done by selecting the input and pressing the spacebar to toggle between High and Low.

The Resistor and +ve power supply must not left out or the tool setter will not work.

The Resistor must not be replaced with a direct connection to the power supply to the input or you will cause a short circuit when the tool touches the touch off.

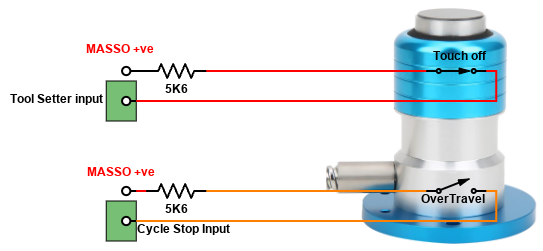

Wiring example of a Tool setter with built in switch

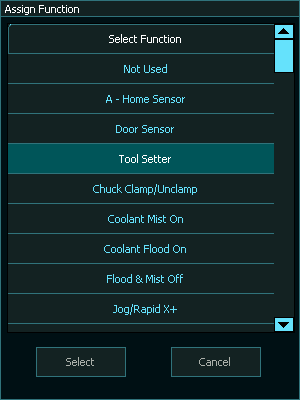

Assigning the Touch plate input

Once the probe has been wired to one of the MASSO inputs, go to the F1 - Setup screen and assign the input as Tool Setter

CAUTION: The input status must show LOW when the Tool setter is not being touched and should only show HIGH when triggered.

INFORMATION: To invert the input signal, invert by selecting the input in the INPUTS list and press the space-bar key on the keyboard. These settings are automatically saved.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese