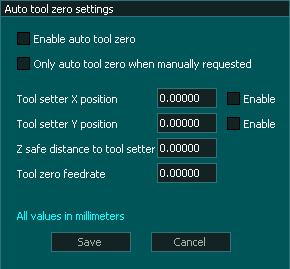

Auto Tool Zero Settings

Enable auto tool zero

- This enables the auto tool zero function used for measuring tool length during the homing routine and between tool changes.

- Without a tool setter installed each tool change will require it's own separate Gcode file as the tool setter is an intergral part of changing tool in MASSO for both manual and Auto tool changers.

- For additional information on Auto tool zero please see: >> Auto Tool Zero

Only auto tool zero when manually requested

- This setting is used for those who have auto tool changers or tools installed in tool holders such that the tool length is fixed.

- When ticked this prevents the tool in the spindle being measured during homing and on tool changes and MASSO uses the tool length entered in the F4 tool table to set the tool height for each tool when change in a Gcode program.

- When this option is selected tools must be measured using the Auto tool zero option if the tool editing page in the F4 page. Each tool only needs to be measured when initially installed in it's holder or is replaced.

- For additional information on Auto tool zero please see: >> Auto Tool Zero

Tool setter X & Y position

- This setting defines the machine coordinate of the Tool setter on the table.

- If the enable is not selected the spindle will not move that axis to the specified coordinate

- The tool setter must be located within the soft limits of the table.

- For additional information on Auto tool zero please see: >> Auto Tool Zero

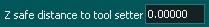

Z safe distance to tool setter

- This defines the machine coordinate that the Z axis ca rapid down to before it starts probing the tool length

- This is useful on long Z axis

- For additional information on Auto tool zero please see: >> Auto Tool Zero

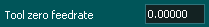

Tool zero feedrate

- This defines the feed rate that the spindle will probe down to the tool setter.

- For additional information on Auto tool zero please see: >> Auto Tool Zero

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese