WaterJet

WARNING: When using waterjet ensure that Auto Spindle Start is disabled in the F1 / Main Spindle settings screen.

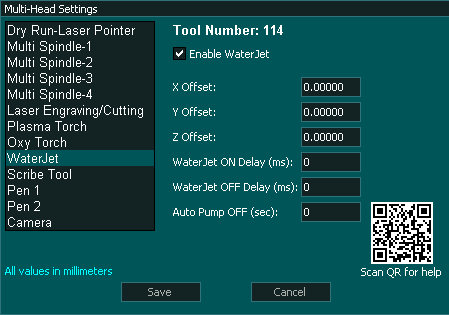

- Tool 114

- To change to Waterjet issue a T114 M06 command in MDI and include this in your Gcode file to ensure that it changes to the correct screen when you run your Gcode file

- The X, Y & Z offset relative to another head can be entered in the Multi-Head Setting page

- M03 Starts the WaterJet.

- M05 Stops the WaterJet

- There are no other GCodes associated with the WaterJet. The manner of operation is selected by use of the on screen mode buttons

and

and

- A range of WaterJet related inputs and outputs have been provided and these can be assigned to one of the inputs or TTLs outputs on MASSO as needed.

Multi-Head Setting

F2 Screen

Cutting Modes

Cut modes are selected manually from the F2 screen using the  and

and  buttons

buttons

WaterJet has 3 cutting modes

- Water Only

- Abrasive Cutting

- Abrasive Cutting with LP Piercing

Water Only Mode

Logic

- Cycle Start to run Gcode file

- M03

- Waterjet on/off changes to High to turn on

- MASSO waits for the Waterjet Cut sense input to change to High

- Motion / Cutting from Gcode file

- M05

- Waterjet on/off changes to Low to turn off

- End

Abrasive cutting Mode

In this mode cutting is done with water and abrasive

Logic

- Cycle Start to run Gcode file

- M03

- WaterJet abrasive on/off changes to High to turn on the abrasive

- MASSO waits for the WaterJet On Delay time

- Waterjet on/off changes to High to turn on

- MASSO waits for the Waterjet Cut sense input to change to High

- Motion / Cutting from Gcode file

- M05

- WaterJet abrasive on/off changes to Low to turn off the abrasive

- Waterjet on/off changes to Low to turn off

- End

Abrasive Cutting Mode with Low Pressure Piercing

In this mode cutting is done with water and abrasive but the initial piercing is done under low pressure.

Logic

- Cycle Start to run Gcode file

- M03

- WaterJet Low Pressure on/off changes to High to enable low pressure during piercing

- WaterJet abrasive on/off changes to High to turn on the abrasive

- MASSO waits for the WaterJet ON Delay time

- Waterjet on/off changes to High to turn on

- MASSO waits for the Waterjet Cut sense input to change to High

- WaterJet Low Pressure on/off changes to Low to allow full pressure during cutting

- Motion / Cutting from Gcode file

- M05

- WaterJet abrasive on/off changes to Low to turn off the abrasive

- WaterJet Low Pressure on/off changes to High to enable high pressure bleed off.

- MASSO waits for the WaterJet OFF Delay time

- Waterjet on/off changes to Low to turn off

- End

On Screen Buttons

WaterJet - on/off

WaterJet - on/off

Waterjet - Abrasive on/off

Waterjet - Abrasive on/off

Waterjet - Low Pressure on/off

Waterjet - Low Pressure on/off

WaterJet - Pump on/off

WaterJet - Pump on/off

WaterJet - Shield on/off raises and lowers the shield manually as needed

WaterJet - Shield on/off raises and lowers the shield manually as needed

This places the Waterjet into Abrasive cutting mode

This places the Waterjet into Abrasive cutting mode

This enables Low Pressure Piercing mode

This enables Low Pressure Piercing mode

WaterJet - Air On/Off and is available only on the MDI screen

WaterJet - Air On/Off and is available only on the MDI screen

WaterJet - Tap Water On/Off and is available only on the MDI Screen

WaterJet - Tap Water On/Off and is available only on the MDI Screen

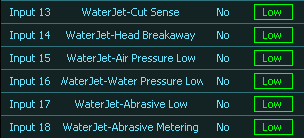

Inputs

WaterJet - Cut Sense

Monitors feedback from the Cutting Valve - Active High

If the Cut Sense input does not change to High within 5 seconds of the water jet starting or it changes to Low during the cut a Cut Sense alarm will result and the machine will stop.

If you do not have this input, do not assign it and MASSO will ignore and start cutting immediately after the WaterJet On Delay timer expires.

WaterJet - Head Breakaway

If the cutting head runs into material or comes loose this input goes High and stops the machine triggers an alarm.

WaterJet - Air Pressure Low

This input monitors the water pressure and if the input goes High it triggers an alarm

WaterJet - Water pressure Low

This input monitors the water pressure and if the input goes High it triggers an alarm.

WaterJet - Abrasive Low

This input monitors abrasive levels and if the input goes High it triggers an alarm.

WaterJet - Abrasive Metering

This input monitors the abrasive and if the input goes High it triggers an alarm.

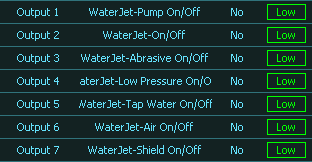

Outputs

WaterJet - Pump On/Off

This output is used to turn the Main WaterJet Pump on and off and is controlled via the  button on the F2 screen.

button on the F2 screen.

WaterJet - On/Off

This output turns opens the waterjet valve for cutting. It is controlled via the M3 command or by using the  button on the F2 screen.

button on the F2 screen.

WaterJet - Abrasive On/Off

This output turns on and off the abrasive and is active when Abrasive Cutting Mode is selected.

It can also be manually turned on and off using the  button on the F2 Screen

button on the F2 Screen

WaterJet - Low Pressure On/Off

This output turns on and off the Low Pressure and is active when LP Peircing Mode is selected.

It can also be manually turned on and off using the  button on the F2 Screen

button on the F2 Screen

It is used to perform High Pressure Bleed off and Low Pressure Piercing.

WaterJet - Tap Water On/Off

This output is used to top up the water tank as needed.

It is turned on and off manually using the  button on the MDI screen. CTRL+M

button on the MDI screen. CTRL+M

WaterJet - Air On/Off

This output is used to turn on an air solenoid as required.

It is turned on and off manually using the  button on the MDI screen. CTRL+M

button on the MDI screen. CTRL+M

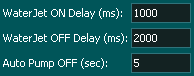

Timers

These timers are found on the WaterJet Multi-Head Settings screen

WaterJet ON Delay (ms):

This timer defines the time delay needed to allow the machine to configure itself for Low pressure and Abrasive modes

This timer is defines in milliseconds.

WaterJet OFF Delay (ms):

This timer defines the time delay is used at the end of the cutting cycle after turning off the Low Pressure for High Pressure Bleed off before turning off the Waterjet.

This timer is defined in milliseconds.

Auto Pump OFF(sec)

This timer will automatically turn off the Pump if cutting is not started before this timer expires.

Each time cutting is started the timer resets and starts counting down again after the cutting is stopped.

If the timer is set to 0 the Pump will not automatically turn off.

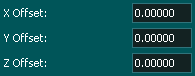

Offsets

These offsets define the WaterJet heads position relative to another head you may have on your machine.

If this is the only head you have on the machine or you do not wish to use this head in combination with another head then these values can be left at 0

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese