How Tool Setter Works

Overview

A tool setter or a simple touch plate can be wired to MASSO and is used as a reference surface with the Auto Tool Zero feature.

When MASSO is homed the tool currently installed in the spindle is touched off of the tool setter.

From this touch off MASSO can measure the length of the tool in the spindle and stores this length to use as a comparison in future tool changes. This value will remain valid until the machine is homed again or it is turned off. The tool can now be zeroed to the surface of the stock as required.

WARNING: Golden Rule If you do change or alter the tool height after homing without being instructed to do so by MASSO or you must home your machine again. Failing to do so will cause the 2nd tool change and all following tool change heights to be wrong causing damage to your work and machine. Do not Home the machine, swap the tool in the spindle without using an M06 Gcode command and then zero your cutter. The measured length of the tool in the spindle when you homed the machine is the reference by which all other tools are calculated. If you change it's length without using the M06 command this reference is no longer valid and all calculated lengths will be incorrect.

When MASSO is asked to change tool using the M06 GCode command it will measure the new tool length and compare it against the original measured tool, then adjust the tool height offset accordingly.

It is therefore critical that once the tool is measured that it is not changed or it's length altered as this will give incorrect tool heights on all future tool changes.

Because the Tool setter is a reference surface the thickness of the tool setter does not matter so long as it does not change it's height.

The tool setter should not be confused with a probing touch plate which is used to measure tool height above the surface of the material which requires the thickness of the probing plate to be known.

Prerequisites

To use a tool setter you must have homing setup on you machine so that the spindle can find the tool setter.

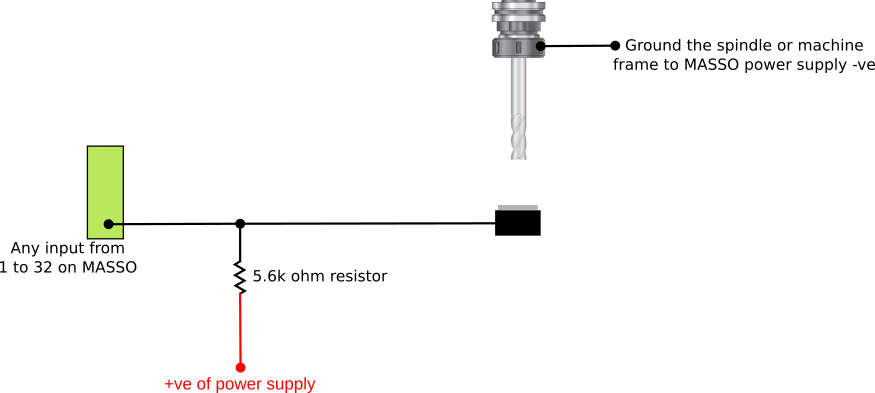

Wiring example of a simple touch plate

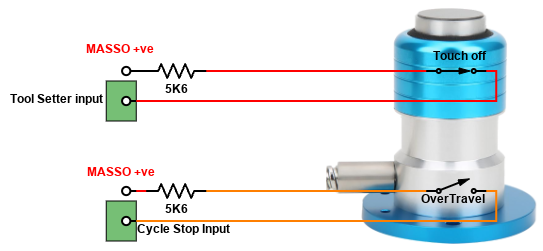

Wiring Example using Touch off with built in switch

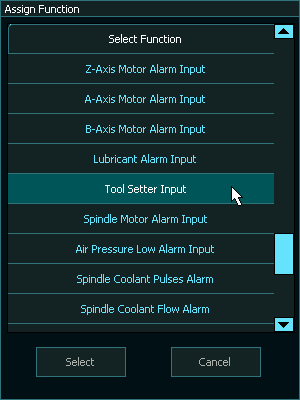

Assign Tool Setter Input

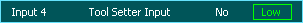

Tool Setter Logic

Manual Tool Change

The Tool setter can be used with manual tool change as well as automatic tool changers.

When you manually change a tool MASSO will move to the Tool Setter and touch off. It will then automatically calculate the new tool height and continue machining having compensated for the difference in tool height.

How to Video

This video takes you through setting up a Tool setter step by step.

Troubleshooting

Tool length wrong after a changing tool

The biggest cause of incorrect tool length after a tool change when using the Auto tool zero is changing the tool that was used when the machine was homed without using the M6 Gcode command.

This alters the reference tool length that is used to calculate all tool changes and all tools after the first one will have an incorrect length.

This can easily be done without thinking as illustrated below

- If you home the machine change the tool in the spindle because it is the wrong one for the job, Zero the tool and start machining and from now on all of the tool heights will be wrong and will chow up on the next tool change.

- The correct method is to change the tool first then home the machine to measure the reference tool length and your Auto tool setter will work correctly.

- Alternatively, zero the current tool to the stock and when MASSO runs the Gcode file it will change the tool and set the correct tool height.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese