High Speed Rotary Tool Changer

This tool changer is for MASSO G3 and MASSO Touch and is only available in Beta version 5.100b or higher.

This tool changer has been tested in the following model tool changers and may be suitable for other similar models.

Please let MASSO Support know if your tool changer model works and we will add it to the list.

- Brother TC-211

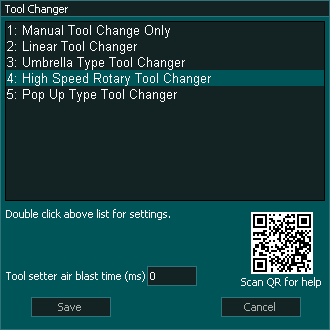

Selecting the tool changer

In the Tool Changer window select High Speed Rotary Tool Changer and double-click for settings.

INFORMATION: The Tool setter air blast is used to clean dust from the tool setter after the tool has been changed and before the tool is measured. It is not used during the tool change process.

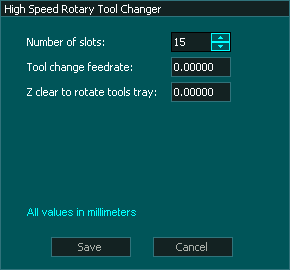

Settings

Number of Slots: Up to 15 tool slots can be assigned.

Tool Change Feedrate: Defines how fast the Z axis moves up and down during the tool change.

Z Clear to Rotate tools tray: This is the machine coordinate that the spindle moves up before the tool tray rotates.

Tool Changer Inputs and Outputs

Syntax used in this document for Tool Changer inputs and outputs

"Tool Changer - Output 1" means Tool Change - 1 and it is an output

"Tool Changer - Input 1" means Tool Changer -1 and it is an Input

Note: Any tool changer input or output can be assigned to any Input or Output on MASSO. The tool changer number does not refer to an actual input or output port.

INFORMATION: If your machine does not have a sensor for one or more of the inputs below then do not assign an input to that function and the tool change logic will ignore the input and will continue.

INPUTS

- Tool Changer - Input 1 for Spindle in INDEX position

- Tool Changer - Input 2 for Clear to rotate tools tray signal

- Tool Changer - Input 3 for Tool position bit 1 signal from the tool changer

- Tool Changer - Input 4 for Tool position bit 2 signal from the tool changer

- Tool Changer - Input 5 for Tool position bit 3 signal from the tool changer

- Tool Changer - Input 6 for Tool position bit 4 signal from the tool changer

- Tool Changer - Input 7 for Tool changer deceleration range

OUTPUTS

- Tool Changer - Output 1 for Spindle INDEX start

- Tool Changer - Output 2 for Spindle clean air blast

- Tool Changer - Output 3 to rotate Tools Tray CW

- Tool Changer - Output 4 to rotate Tools Tray CCW

Tool Changer logic

When a tool change command is received, the tool changer logic works in the followings steps:

- The spindle is turned OFF and the system waits for the spindle to stop as per the spindle "Spin down delay" value in the spindle settings.

- The system checks if the current tool in the spindle is setup in a slot is the F4-Tools screen, else gives an error.

- The system checks if the tool to load is setup in a slot is the F4-Tools screen, else gives an error.

- Tool Changer - Output 1 for Spindle in INDEX position goes High to start index process

- The system waits for the "Tool Changer - Input 1 (Spindle in INDEX position)" to go HIGH to signal spindle is indexed, otherwise it gives an error.

- Z-Axis moves UP past the homing switch until Tool Changer Input 2 (Clear to Rotate Tools) goes HIGH. The homing switch is pressed the entire time it is in tool change.

- "Tool Changer - Output 3 or 4" goes HIGH to Rotate the Tools tray depending on the direction of rotation required.

- The system reads 4 digital inputs from the positioning sensor:

- Tool Changer - Input 3: (bit 1)

- Tool Changer - Input 4: (bit 2)

- Tool Changer - Input 5: (bit 3)

- Tool Changer - Input 6: (bit 4)

- Then the system waits for Tool Changer - Input 7 signal to check if the new tool is in the correct position.

- Once the desired tool is in position the "Tool Changer - Output 3 or 4" goes LOW to stop tools rotation.

- Tool Changer - Output 2 (spindle clean air blast) goes HIGH

- Z-Axis moves DOWN

- Tool Changer - Output 2 (spindle clean air blast) goes Low when Z axis is back below homing switch.

- Tool Changer - Output 1 goes LOW to allow normal spindle control.

- Tool change compete.

INFORMATION: All input & output signals can be easily inverted by selecting the input or output in the list and pressing the space-bar key on the keyboard to invert the signal. These settings are automatically saved.

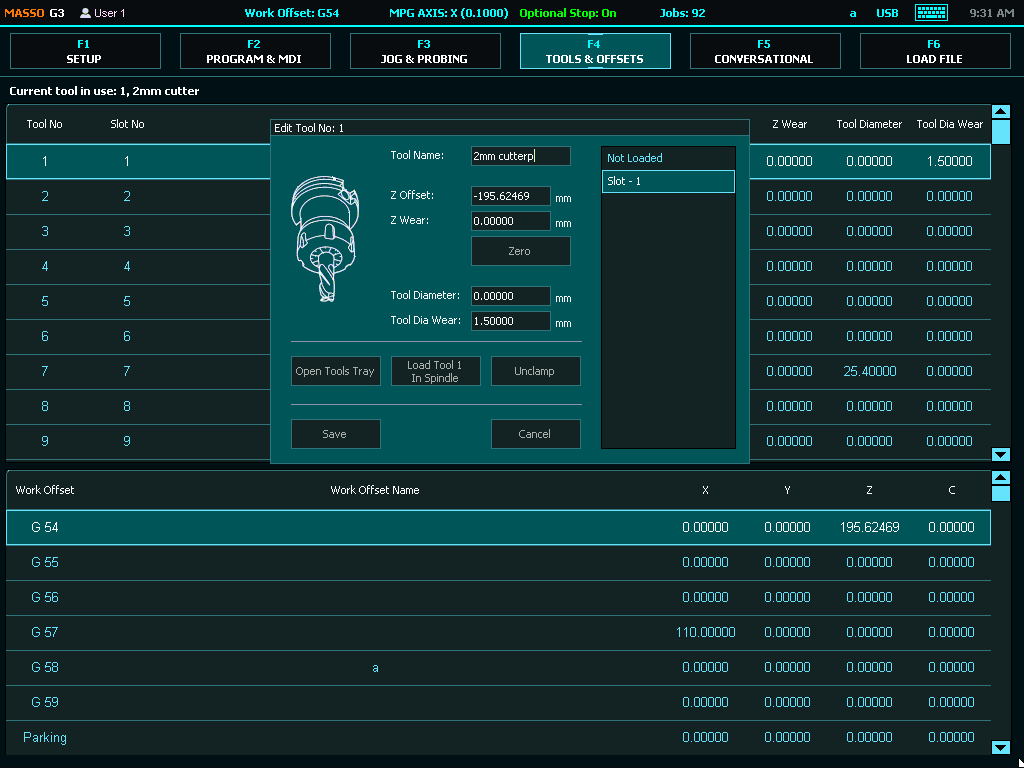

INFORMATION: Make sure to assign each tool into a tool slot in the F4 - Tools & Work offset screen else on a tool change command if the tool is not set in a slot you will get a tool error alarm.

INFORMATION: Tool Changers may be placed outside of soft Limits to protect them from accidental damage however the Auto Tool Zero must remain within soft limits.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese