Lathe Tool Calibration Steps

INFORMATION: On a lathe machine X-axis work offsets are not used or available because changing the X offset would result in a change of workpiece diameter. For setting the X offset to calibrate each tool, please follow the below procedures.

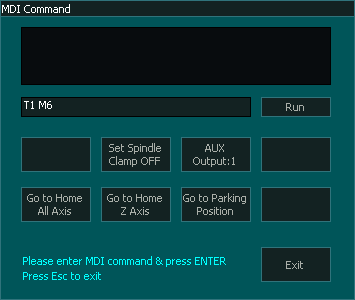

Step 1: Open the MDI window using the MDI button in F2 Screen or CTRL+M and load the tool you would like to calibrate, in this example we will be calibrating Tool No.1.

Step 2: Machine a small test piece or use an existing piece.

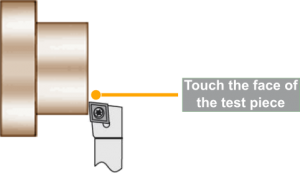

Step 3: Go to F3 – Jog/Rapid screen and touch the tool to the front face of the test piece.

Step 4: Go to F4-Tools & Work Offset screen and open the tool number you want to calibrate.

Step 5: Give a name to the tool for your reference and click the Zero button.

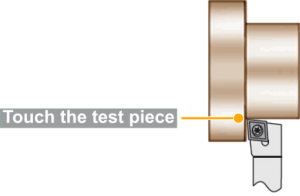

Step 6: Now go to F3 – Jog/Rapid screen and touch the tool to the side of the test piece.

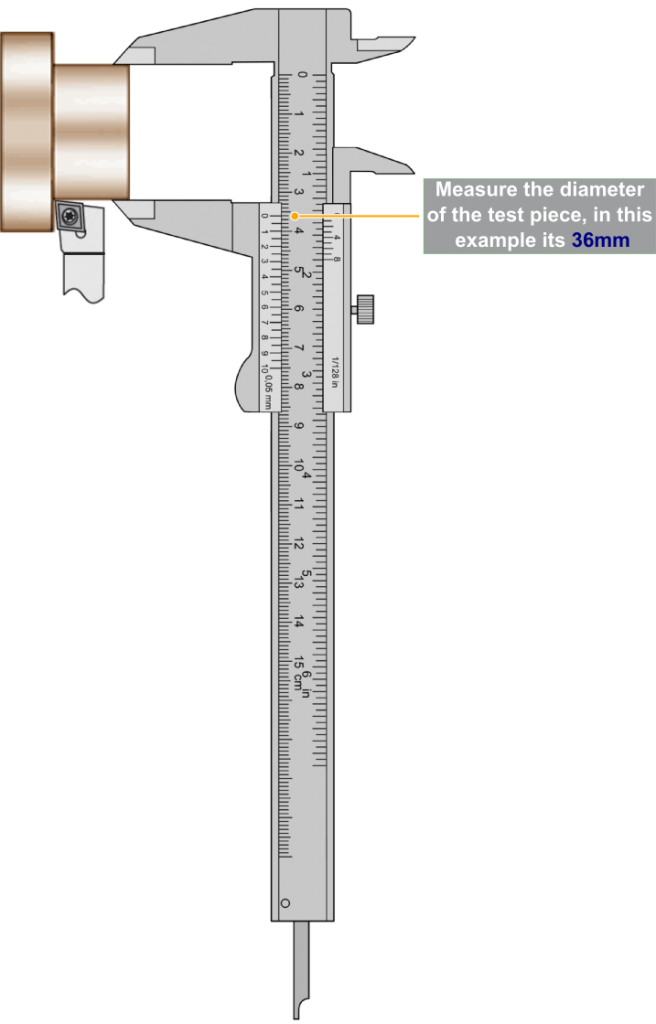

Step 7: Measure the diameter of the test piece and note the value.

WARNING: Do not Jog or move the tool away unit the next step has been completed.

Step 8: Go back to F4-Tools & Work Offset screen and enter the measured diameter value in Test Piece (Dia) box and click the Touch button.

CAUTION: Make sure to select the position of the tool depending if it is installed on the front or the backside.

Step 9: Next select if the tool is on the front side or the backside and make sure that the Z Wear and X Wear values are 0.00.

Step 10: Click the Save button to save and complete tool calibration.

Spanish

Spanish  French

French  German

German  Simplified Chinese

Simplified Chinese